Machine Show

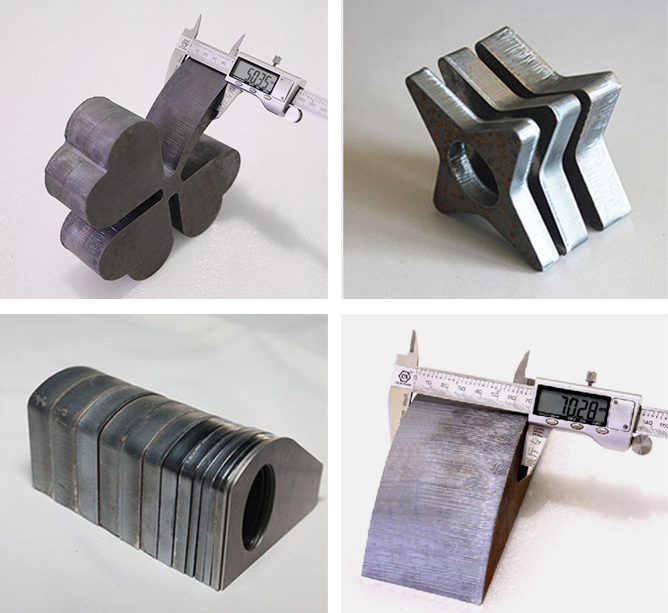

Cutting Show

Customer Voice

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

GWEIKE laser cutting machine YLS-CUT series high power fiber laser of IPG. Powerful cutting ability with stainless steel, aluminum and other metal materials, cutting thickness is up to 40mm.

The world leading IPG laser has stable performance, the service life can reach 100000 hours, and the overall quality of the equipment can be guaranteed safely.

Fiber laser source can produce excellent beam quality, finer cutting lines, higher working efficiency and better machining quality. Fully closed constant temperature working environment makes laser source more effective to ensure the stable operation.

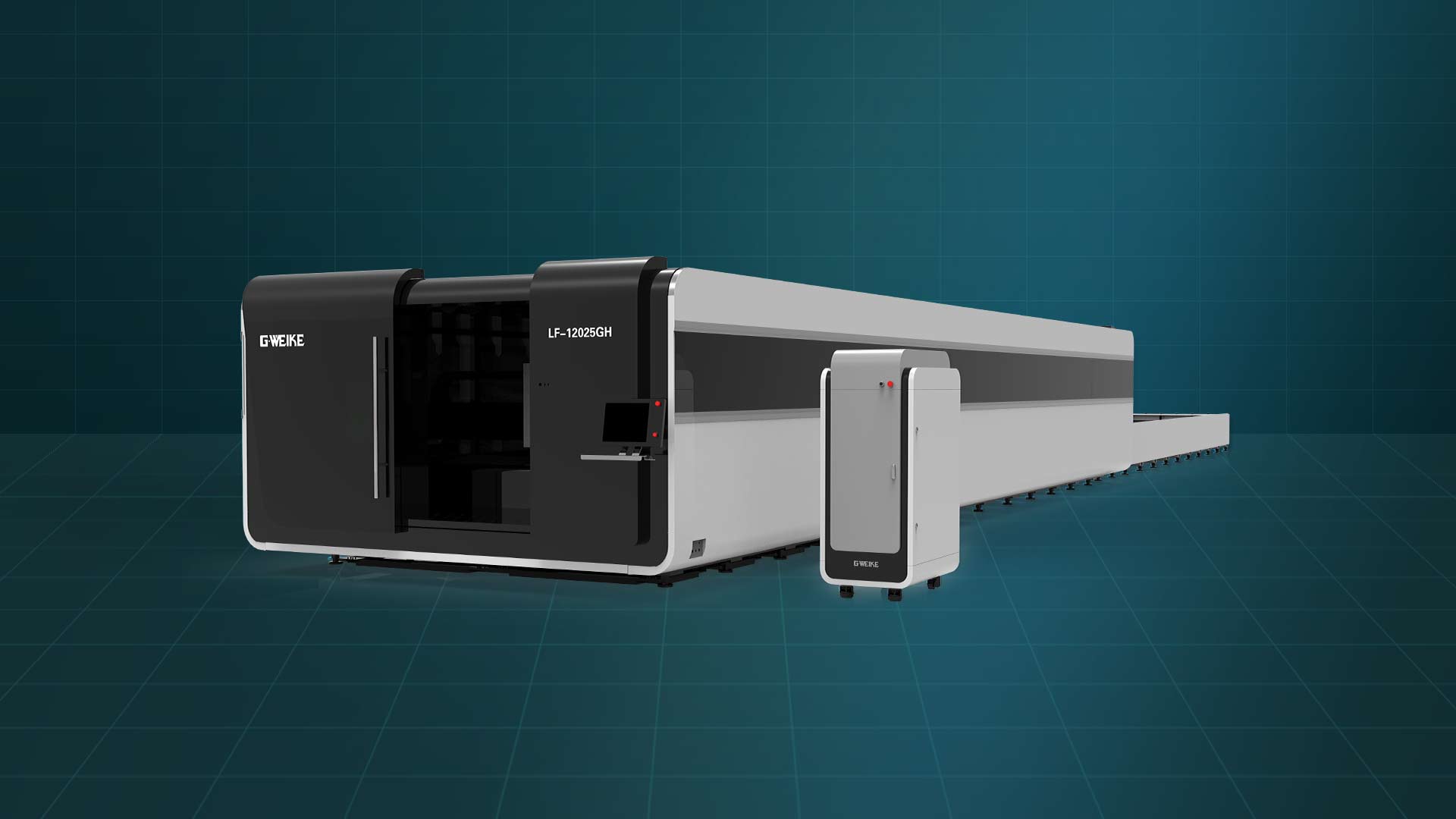

Gweike laser large format equipment includes 12025G (12m*2.5m), 10025G (10m*2.5m) The overweight bed process meets the diverse needs of the global market for large sheet metal cutting High-end, high-precision, high-speed, high-format and cost-effective.

Full coverage, super suction

Adopt the latest cutting-edge tobacco control technology

Each section of the bed has a smoke exhaust device

Powerful negative pressure 360° adsorption

Axial fan wind direction surrounds blowing smoke downward

Full 360° strong adsorption and consistent smoke exhaust

Effectively purify the smoke and dust on the top of the enclosed cutting platform

Improve purification efficiency and reject lens contamination

Net follow-up, wisdom grows by quality

The smoke exhaust device automatically senses the laser cutting position

Turn on precise smoke exhaust, follow-up smart smokingCreate a concealed cavity, fully enclosed smoke control and clean smoke

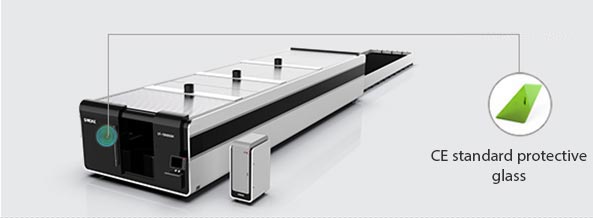

Fully enclosed design; the observation window adopts European CE standard protective glass; the smoke generated by cutting is internally filtered, and the emission is up to the standard, without pollution;

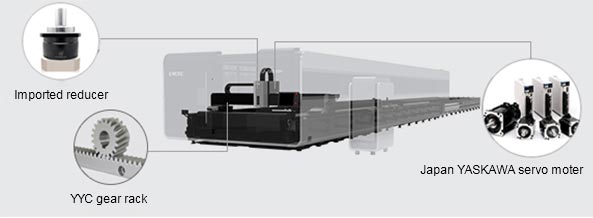

It adopts Japanese Yaskawa motor, Taiwan Shangyin rack, and French motor reducer. The positioning accuracy of the machine tool is 0.02.

During the processing, each blind spot area can be monitored at any time, and the cutting process can be controlled; the high-definition intelligent monitoring system, remote alarm operation is no danger.

LF12025GH is widely used in sheet metal processing, guardrail processing, chassis cabinets, electronic equipment, auto parts, machinery equipment, agricultural machinery, hardware products, kitchenware, doors and windows, lamps, handicrafts, display equipment, fitness equipment and other industries. Used for cutting carbon steel, stainless steel, aluminum and other materials, the cutting thickness can reach 70MM, galvanized sheet, electrolytic plate, aluminum alloy, brass and copper and other metal materials, so that your laser processing "thick" hair.

| Machine model | LF4020GH | LF6025GH | LF10025GH | LF12025GH |

| Laser power | 8000W 12000W 15000W 20000W(Optional) | |||

| Dimensions | 11475*2574*5169mm | 14937*3952*2287mm | 22953.5*4006*2336.5mm | 27092*4119*2336.5mm |

| Working area | 4000mm*2000mm | 6000mm*2500mm | 10000mm*2500mm | 12000mm*2500mm |

| Repeat positioning accuracy | ±0.02mm | |||

| Maximum speed | 200m/min | |||

| Max. acceleration | 2.5G | |||

| Voltage and frequency | 380V 50Hz/60HZ | |||

PROFESSIONAL LASER