New surface modification technology

Strong material compatibility

Maximum turning radius

1831mm

Workpiece processing shaft diameter

Φ≤800mm

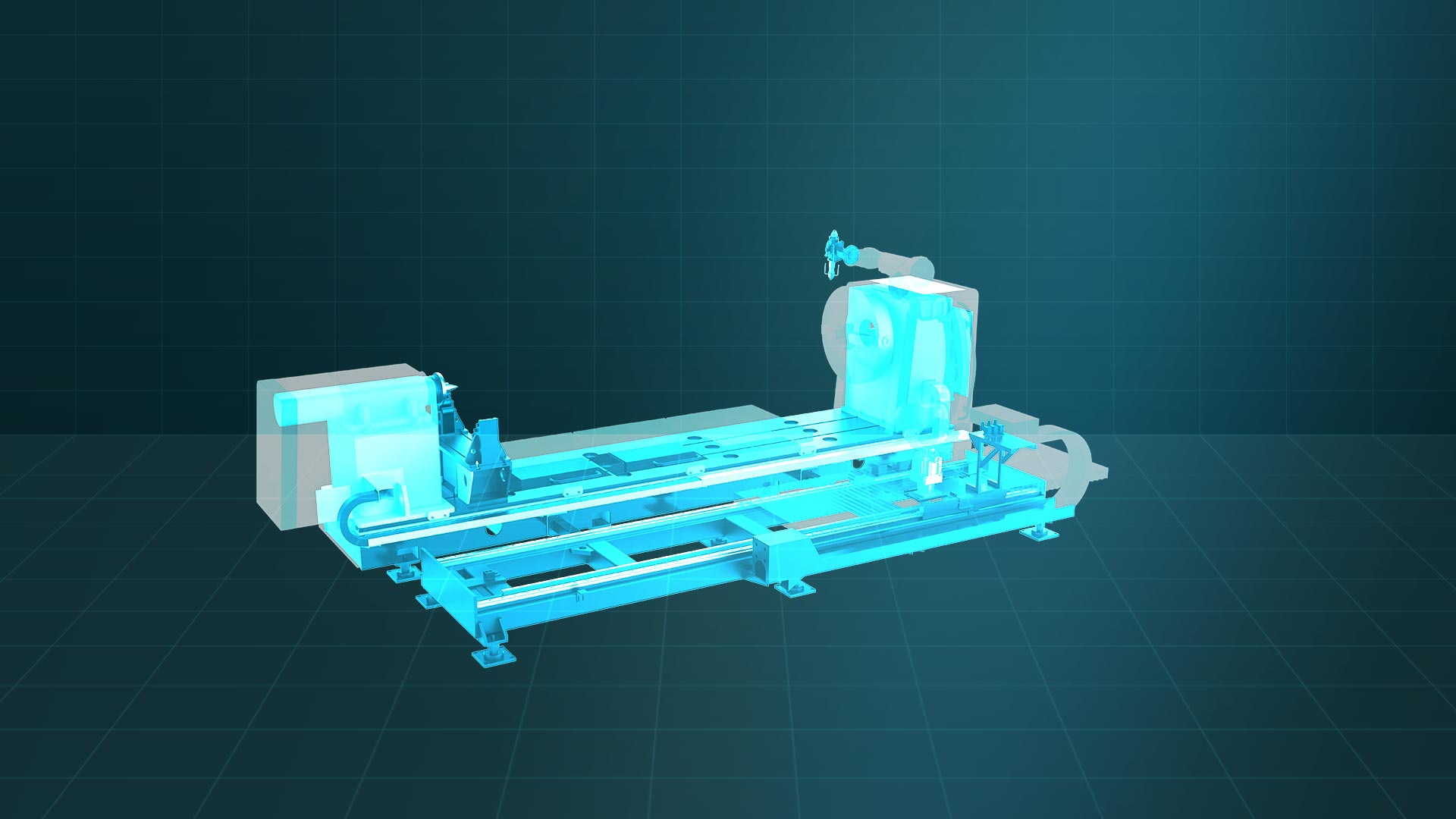

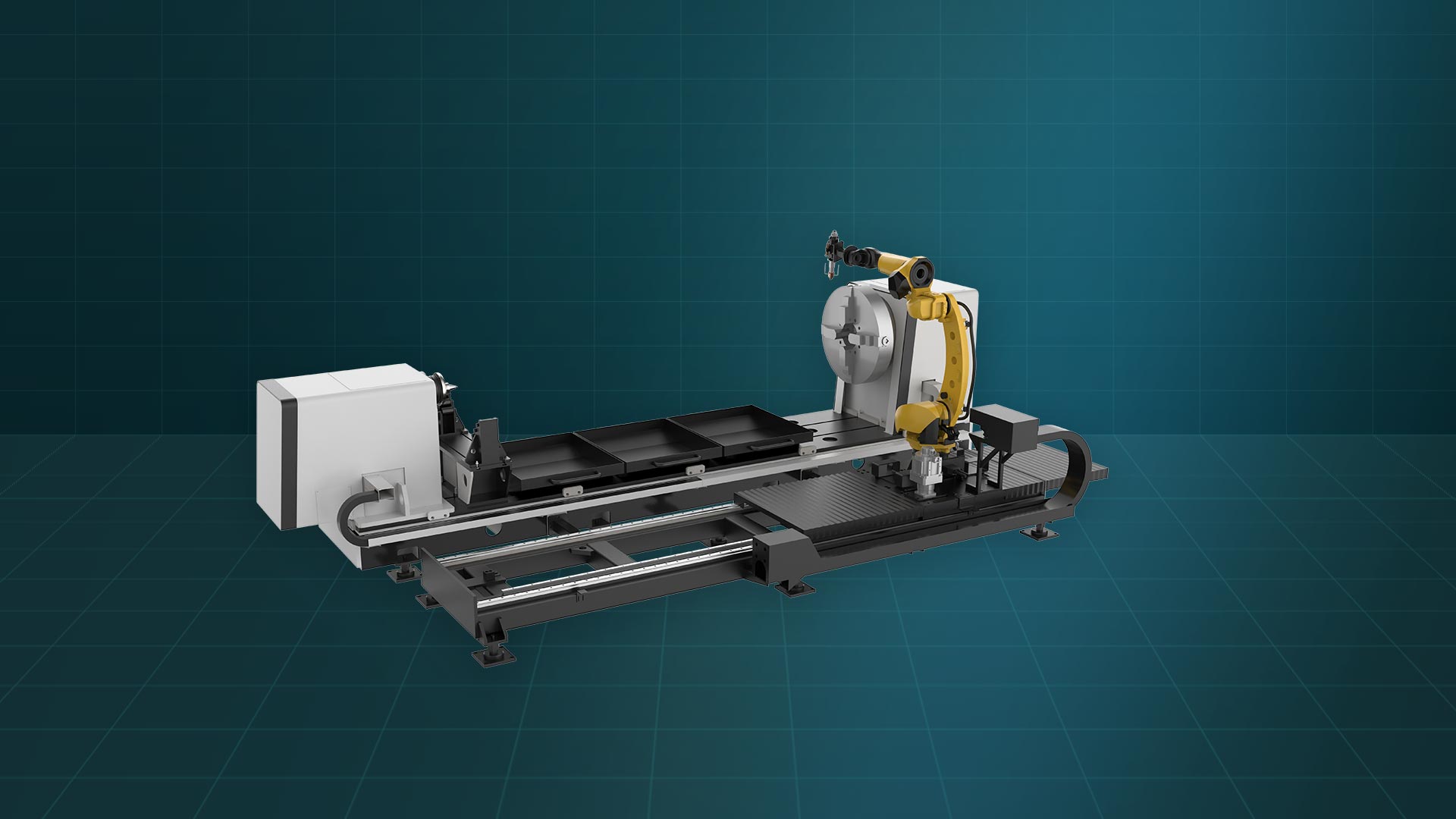

Laser cladding processing is carried out using a robotic arm equipped with optical fibers and cladding heads. The robotic arm is installed on a moving slide and controls the forward and backward movements of the moving slide, driving the robotic arm to move forward and backward, achieving workpiece cladding processing; The workpiece is fixed on the workbench through the front chuck and the rear center tailstock. The rotation of the front chuck drives the workpiece to rotate, and the tailstock moves forward and backward through lifting.

① Low dilution

② Good adhesion between coating and substrate

③ Suitable for cladding with multiple materials

④ Large changes in particle size and content

The wide application of laser cladding technology can effectively solve the phenomenon of failure and scrap equipment and parts, and can also extend the life span of new products, and achieve the effect of multi-life cycle.

| Machine model | GKS-LC3008R |

| Laser power | 4000W-12000W |

| Motion mechanism | 6 axis industrial robot |

| Maximum turning radius | 1831nm |

| Workpiece machining shaft diameter | φ≤800mm |

| Equipment maximum load | ≤3000kg |

| Work piece length | ≤3000mm/td> |

| Device positioning accuracy | ±0.05mm/m |

| Repeat positioning accuracye | ±0.03mm/m |

| Achievable layer thickness | According to customer process requirements |

| Deposition efficiency | According to customer process requirements |

| According to customer process requirements | |

| Number of control axes | 6 axis |

| Wrist load | 25kg |

| Working radius | 1831mm |

| Repeat positioning accuracy | ±0.02mm |

| Wrist range of motion | 0-180° |

| Main technical parameters of wide belt cladding head | |

| Power | 6KW |

| Numerical aperture NA | ≤0.25 |

| Applicable wavelength | 900-1100nm |

| Collimator | 100, 120, 300mm (optional) |

| Focal length | 250, 300, 400mm (optional) |

| Fiber interface | QBH, LLK, QD |

| Powder feeding nozzle | Circular powder feeding |

| Powder convergence spot | 2mm (can be customized according to specific needs) |

PROFESSIONAL LASER